Calibration is the process used to ensure instruments and equipment function according to their manufacturer’s specifications across their intended operational ranges. Simply put, it involves checking and adjusting devices to maintain accuracy, predictability and reliability.

In this post, we’ll explore the fundamental aspects of calibration, including:

- Why it’s necessary

- What it involves

- When it should be performed

- Who should conduct it

Why Does Equipment Need Calibration?

Over time, all equipment experiences some degradation. As components age, they lose stability and can drift from their published specifications. Even normal handling can adversely affect calibration, and rough handling can throw a piece of equipment completely out of calibration, even if it appears to meet physical standards.

Regular calibration assures that equipment continually meets the specifications required. Having a well-designed and organized calibration program benefits operational quality and productivity, increasing revenue.

What Is Being Measured and Adjusted?

Measurements and adjustments are made within certain tolerances, which represent very small, acceptable deviations from the equipment’s specified accuracy. Calibration is certified with a report or certificate assuring the end user of a product’s conformance with its specifications.

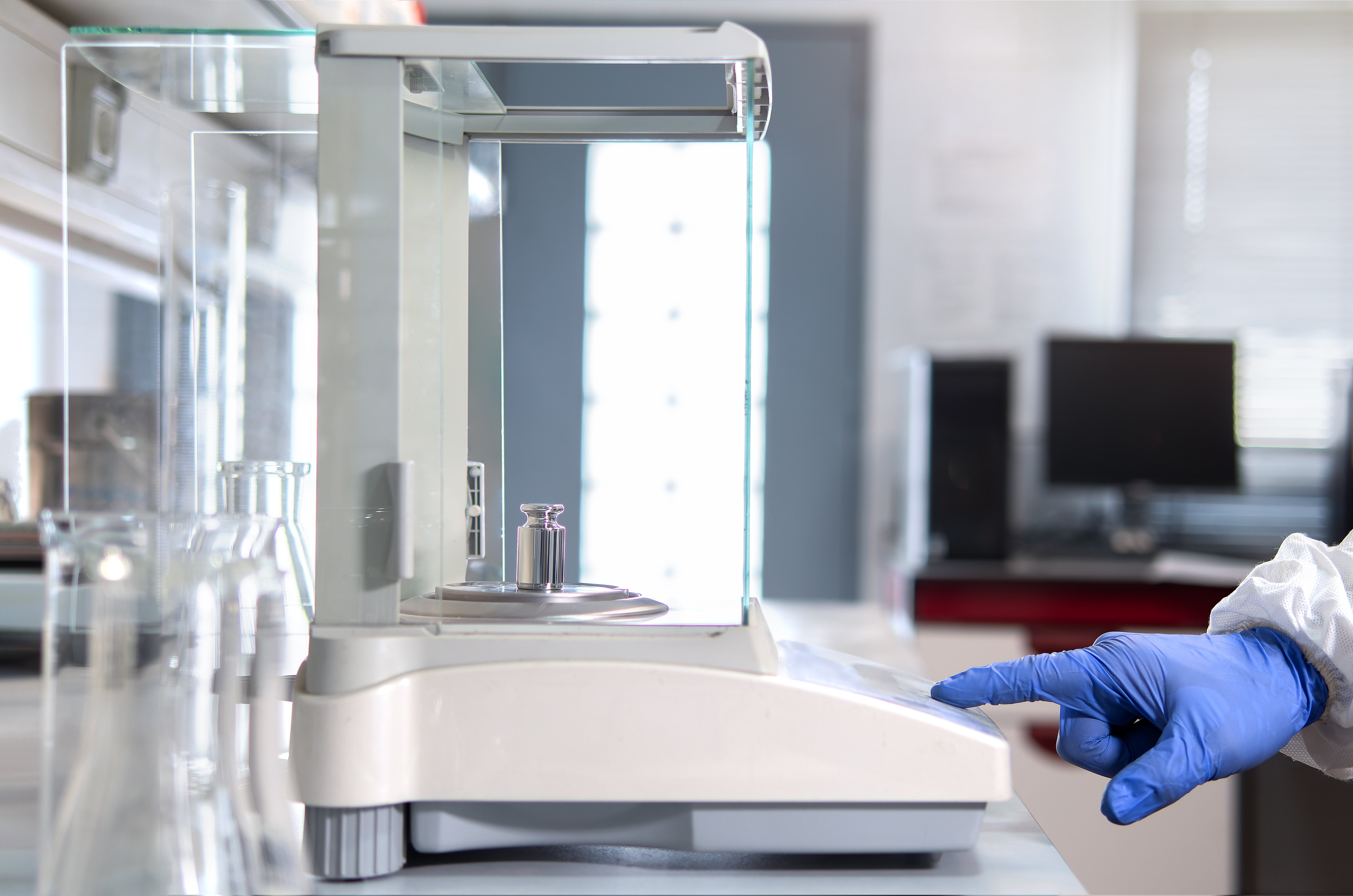

Calibration is carried out by comparing the readings or dimensions of an instrument with those given by a reference standard. Reference instruments are regularly calibrated with a recognized national standard.

When Is Calibration Needed?

Calibration intervals can vary greatly within an industry or plant. Frequency depends on equipment and the application. As a rule, however, calibration should be performed at least once a year. In more critical applications, more frequent adjustments are necessary.

Who Performs Calibration Services?

When planning and implementing a calibration program, it is important to use a qualified provider that adheres to national standards. Choosing a company with accreditation to the ISO 17025 standard is the best choice and in some industries, required. ISO/IEC 17025: 2005 sets rigorous standards for laboratory testing and calibration.

Accredited calibration providers have oversight protection through their accrediting body with regular audits, reviews and specific Quality Management System requirements.

Joe Moser - CEO

Joe Moser - CEO